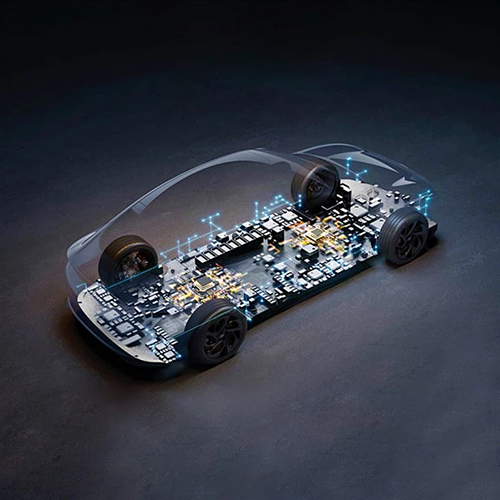

Sweeping Robots PCBA Services

Product Details:

X

Product Description

Sweeping Robots PCBA Services involve the manufacturing and assembly of the electronic components that power and control these autonomous cleaning devices. It is capable of handling both small-scale and large-scale production runs, catering to diverse market needs. They offer ongoing technical assistance and documentation for assembly and maintenance. We design PCBs specifically for the unique functionalities of sweeping robots, including navigation, obstacle detection, and cleaning mechanisms. Comprehensive testing of assembled boards is also done to ensure they meet performance standards and reliability. Sweeping Robots PCBA Services are essential for developing efficient, reliable, and advanced cleaning solutions.

Precision Engineering for Smart Cleaning

Our PCBA solutions are tailored for sweeping robots, integrating smart control and real-time monitoring into reliable circuit design. We utilize high-quality FR4 material, HASL surface finishing, and copper thickness up to 2 oz to guarantee optimal conductivity and durability for automation applications.

Advanced Assembly and Testing

We offer both surface-mount (SMT) and through-hole (THT) assembly types to accommodate diverse component packages, including SMD, DIP, and BGA. Rigorous AOI and functional testing processes ensure defect-free, high-performing PCBA products for sweeping robots.

Flexible Customization, Fast Delivery

With board sizes up to 400mm x 500mm and customizable connector types, we adapt to your design requirements. Our efficient manufacturing processes allow us to deliver completed PCBAs within 7-15 days, providing rapid support for OEM and ODM needs globally.

FAQ's of Sweeping Robots PCBA Services:

Q: How do your PCBA services support different layer counts for sweeping robots?

A: We manufacture and assemble PCBAs with 2-6 layers, enabling complex circuit designs suitable for smart control and real-time monitoring features crucial in sweeping robots.Q: What is the process for testing and ensuring the quality of PCBA for sweeping robots?

A: Our quality assurance process includes Automated Optical Inspection (AOI) and thorough functional testing to verify that each PCBA meets performance and reliability standards before delivery.Q: When can I expect delivery of my sweeping robot PCBA order?

A: Lead times typically range from 7 to 15 days, depending on order specifics and customization requirements, ensuring rapid fulfillment for both OEM and ODM shipments.Q: Where are your Sweeping Robots PCBA manufactured and shipped from?

A: Our PCBA products are manufactured in China, where we operate as an exporter, manufacturer, and supplier, providing global delivery and support for all orders.Q: What component packages and connector types can be used with your PCBA solutions?

A: We support SMD, DIP, and BGA packages, and offer customizable connectors as per your design needs to facilitate flexible integration into different sweeping robot models.Q: How does using your PCBAs benefit sweeping robot applications?

A: Our PCBAs provide robust smart control and real-time monitoring functions, ensuring efficient robot operation, high durability under varying conditions, and seamless adaptability to advanced cleaning system requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PCBA Application Service' category

Back to top

Call Me Free

Call Me Free