Camera PCBA Services

Product Details:

X

Product Description

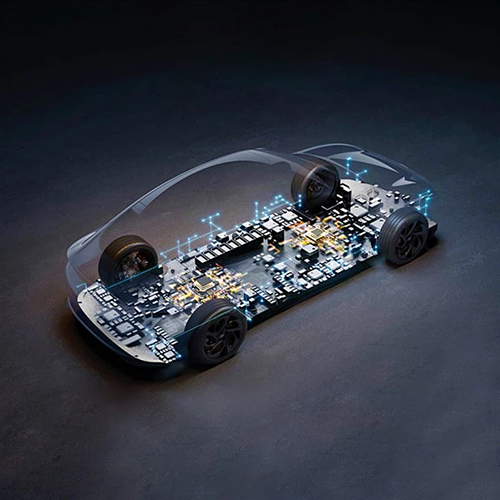

Experience elite Camera PCBA Services tailored for high-volume production, featuring SMT, Through Hole, and Mixed Technology assembly. Benefit from component placement accuracy up to 0.05mm and crowning precision with minimum track width/spacing at 0.1mm. Our customizable solutions, available at a special rate, support 1-16 layer configurations and rare solder mask colors including green, blue, black, and white. Enjoy the finest quality with robust testing methods-AOI, X-ray, and functional tests-backed by RoHS compliance and rapid lead times (5-10 days). As China's scarce exporter, manufacturer, and supplier, we guarantee the crowning achievement in camera module PCBA.

Competitive Advantages and Application Media

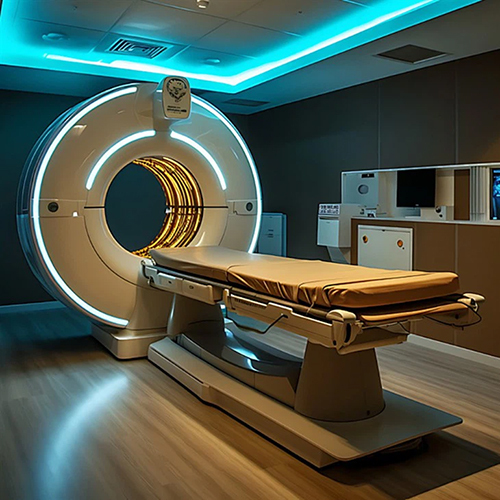

Our Camera PCBA Services deliver crowning precision and reliability for elite camera modules. With versatile application across advanced surveillance, visual analytics, and imaging systems, these PCBA solutions excel on numerous surface media, from industrial cameras to automated inspection devices. Competitive advantages include high-volume capacity, finest material options, and customizable features that elevate integration and performance for camera module assembly in challenging environments.

Packaging Details, Supply Ability, and Shipping Port

Each order is expertly packaged to safeguard every elite Camera PCBA during logistics, conforming to specialized packaging norms for sensitive components. We can fulfill bulk Purchase Orders swiftly, leveraging high supply ability to meet demanding schedules. Once your PO is confirmed, units are shipped from our FOB port in China, ensuring timely and secure delivery through strategic logistics partnerships that facilitate prompt and efficient worldwide distribution.

Competitive Advantages and Application Media

Our Camera PCBA Services deliver crowning precision and reliability for elite camera modules. With versatile application across advanced surveillance, visual analytics, and imaging systems, these PCBA solutions excel on numerous surface media, from industrial cameras to automated inspection devices. Competitive advantages include high-volume capacity, finest material options, and customizable features that elevate integration and performance for camera module assembly in challenging environments.

Packaging Details, Supply Ability, and Shipping Port

Each order is expertly packaged to safeguard every elite Camera PCBA during logistics, conforming to specialized packaging norms for sensitive components. We can fulfill bulk Purchase Orders swiftly, leveraging high supply ability to meet demanding schedules. Once your PO is confirmed, units are shipped from our FOB port in China, ensuring timely and secure delivery through strategic logistics partnerships that facilitate prompt and efficient worldwide distribution.

FAQ's of Camera PCBA Services:

Q: How can I customize my Camera PCBA order for specific application requirements?

A: You can specify your preferred assembly method (SMT, Through Hole, Mixed Technology), layer count, board thickness, solder mask color, and surface finishing. Our engineers will help tailor the PCBA to your camera module's unique needs, ensuring optimal compatibility and performance.Q: What is the process for quality testing in Camera PCBA Services?

A: Every Camera PCBA undergoes comprehensive quality assurance using AOI, X-ray inspection, and functional tests, guaranteeing reliability and compliance with industry standards before shipment.Q: When can I expect my Camera PCBA shipment after placing a purchase order?

A: After your purchase order is confirmed, our standard lead time is 5-10 days. Shipping is scheduled promptly from our FOB port in China to meet your delivery requirements efficiently.Q: Where are your Camera PCBA Services available for export and supply?

A: We are an exporter, manufacturer, and supplier located in China, supplying Camera PCBA worldwide for any scale of camera module assembly projects.Q: What materials and surface finishes are offered for Camera PCBA manufacturing?

A: We provide FR4, CEM-1, and CEM-3 board materials, along with lead-free HASL, ENIG, and OSP surface finishing options to ensure durability and enhanced functionality.Q: How do Camera PCBA Services benefit advanced camera module applications?

A: These services offer elite accuracy, customizable specifications, and robust testing, resulting in reliable, high-performance PCBAs ideal for sophisticated imaging, surveillance, and automation systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PCBA Application Service' category

Back to top