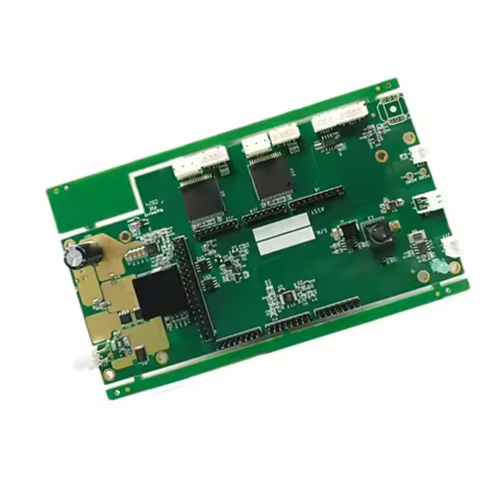

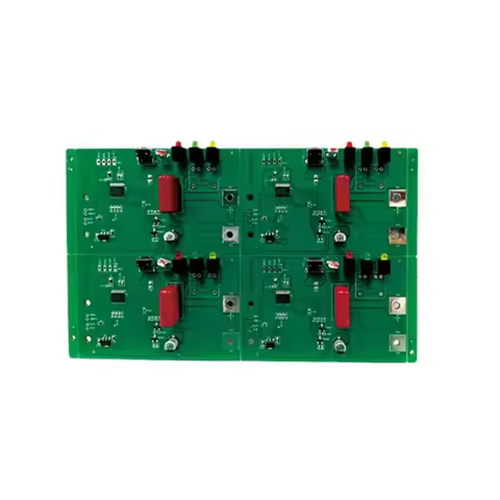

High Quality Flexible PCB Assembly One-Stop Service for PCBA

Product Details:

- Soldermask Yellow, black, green, or customized

- Min. Line Width 0.1mm

- Board Type Flexible PCB

- Insulation Resistance >10^8

- Hole Size Min 0.2mm

- Flame Resistance Level 94V-0

- Min. Line Spacing 0.1mm

- Click to view more

X

High Quality Flexible PCB Assembly One-Stop Service for PCBA Price And Quantity

- 100 Piece

- Rapid prototyping to mass production

- Wearables, Medical Devices, Consumer Electronics, Automotive

- -40°C to +85°C

- Anti-static packaging

- One-stop purchasing service

- ODM/OEM Supported

- ISO9001 & UL Certified

- As per customer specifications

- 1mm min

- RoHS Compliant Manufacturing

- SMT & Through-hole Assembly

High Quality Flexible PCB Assembly One-Stop Service for PCBA Product Specifications

- >10^8

- 1oz, 2oz, 3oz or customized

- Custom as per request

- PCB Assembly

- Min 0.2mm

- HASL, ENIG, Immersion Silver, OSP, etc.

- Red

- 220-440 Volt (V)

- Controlled impedance as required

- Flexible PCB

- Polyimide, PET

- Mounted as per BOM

- Different available Millimeter (mm)

- 94V-0

- Yes

- 0.1mm

- Yellow, black, green, or customized

- White, Black, Yellow or custom

- 100% E-Test and inspection

- Available upon design

- 0.1mm

- 1-12 Layers (customizable)

- Rapid prototyping to mass production

- Wearables, Medical Devices, Consumer Electronics, Automotive

- -40°C to +85°C

- Anti-static packaging

- One-stop purchasing service

- ODM/OEM Supported

- ISO9001 & UL Certified

- As per customer specifications

- 1mm min

- RoHS Compliant Manufacturing

- SMT & Through-hole Assembly

High Quality Flexible PCB Assembly One-Stop Service for PCBA Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 7 Days

Product Description

Experience the latest in high-quality, flexible PCB assembly with our top-drawer, one-stop PCBA service. Personalise every project with fully customizable specifications, from panel size and copper thickness to color and silkscreen shades. We expertly handle SMT and through-hole assembly, pivotal for prototype or mass orders, offering rapid turnaround. All boards are manufactured RoHS-compliant and pass strict ISO9001 & UL certifications. Rely on noteworthy quality assurance, anti-static packaging, and a flexible bending radius down to 1mm for wearables, medical, automotive, or consumer electronics. OEM/ODM support available.

Exceptional Features & Versatile Applications

Our flexible PCB assembly service stands out with its customizable panel sizing, voltage endurance up to 440V, and controlled impedance according to your design. Top-notch flame and insulation resistance make these boards a compelling choice for high-reliability industries. Applications span medical devices, wearables, consumer electronics, and automotive sectors. Additional features include sensor switch integration and choice of soldermask and surface finish, allowing you to tailor the product to your precise requirements.

Supply Ability, Efficient Delivery, and Competitive Charges

With robust supply capabilities and an efficient order processing system, we deliver rapid prototyping up to mass production runs. Your outlay is minimized with our one-stop procurement and assembly approach, streamlining component sourcing and manufacturing. Choose your preferred FOB port in Vietnam for global logistics efficiency. Experience quick turnaround times backed by reliable quality, ensuring your next project remains on budget, on charge, and on schedule.

Exceptional Features & Versatile Applications

Our flexible PCB assembly service stands out with its customizable panel sizing, voltage endurance up to 440V, and controlled impedance according to your design. Top-notch flame and insulation resistance make these boards a compelling choice for high-reliability industries. Applications span medical devices, wearables, consumer electronics, and automotive sectors. Additional features include sensor switch integration and choice of soldermask and surface finish, allowing you to tailor the product to your precise requirements.

Supply Ability, Efficient Delivery, and Competitive Charges

With robust supply capabilities and an efficient order processing system, we deliver rapid prototyping up to mass production runs. Your outlay is minimized with our one-stop procurement and assembly approach, streamlining component sourcing and manufacturing. Choose your preferred FOB port in Vietnam for global logistics efficiency. Experience quick turnaround times backed by reliable quality, ensuring your next project remains on budget, on charge, and on schedule.

FAQ's of High Quality Flexible PCB Assembly One-Stop Service for PCBA:

Q: How can I customize the PCB assembly according to my project's requirements?

A: You can personalise parameters such as panel size, copper thickness, silkscreen color, board thickness, and more to ensure the assembly precisely matches your specifications. Connector types and component mounting are also fully customizable based on your supplied Bill of Materials (BOM).Q: What is the standard turnaround time for prototyping and mass production?

A: Turnaround time depends on the complexity and order quantity, but our streamlined processes ensure rapid prototyping, while mass production timelines are provided upfront during the order processing stage. We prioritize delivering on schedule every time.Q: Where are your manufacturing and export facilities located?

A: Our facilities are based in Vietnam, from where we handle PCB manufacturing, component procurement, assembly, and global export. Customers can select their preferred FOB port for shipment arrangements.Q: What applications are these flexible PCBs most suited for?

A: Our flexible PCB assemblies are pivotal for wearable devices, medical equipment, automotive systems, and a wide array of consumer electronics, thanks to their robust design, controlled impedance, and customizable features.Q: What quality assurance measures are in place for your PCBA services?

A: We adhere to strict ISO9001 and UL certification guidelines, with 100% E-Test and comprehensive inspection to guarantee reliable performance. All products are RoHS compliant, and only anti-static packaging is used for safety.Q: How do I initiate an order and what is the expected outlay?

A: To start an order, simply share your design files, BOM, and specific requirements. Our team will provide a detailed quotation with transparent charges and estimated lead time based on your customization needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Flexible PCBA' category

Back to top

Call Me Free

Call Me Free