0.12mm & 0.15mm Polyimide FPC Assembly 2 & 4 Layers Flexible PCB Circuit Board Assembly Services PCBA Product Line

Product Details:

- Voltage Endurance 220-440 Volt (V)

- Silkscreen White / Black / Custom

- Flame Resistance Level UL94V-0

- Insulation Resistance >10^9

- Impedance Controlled Impedance available

- Soldermask Yellow, Black, Green, Blue, White

- Board Type Flexible PCB, Polyimide FPC

- Click to view more

X

0.12mm & 0.15mm Polyimide FPC Assembly 2 & 4 Layers Flexible PCB Circuit Board Assembly Services PCBA Product Line Price And Quantity

- 100 Piece

- Turnkey, Consignment, Partial Turnkey

- Full SMT & Through Hole Assembly

- Yes

- 1 Piece

- Custom contours and cutouts supported

- Up to 600mm length

- ZIF, FPC, Custom Types

- Vacuum/ESD safe packaging

- Sample: 3-5 working days; Mass Production: 8-12 days

- PI, FR4, Stainless Steel

0.12mm & 0.15mm Polyimide FPC Assembly 2 & 4 Layers Flexible PCB Circuit Board Assembly Services PCBA Product Line Product Specifications

- 0.05mm (2 mil)

- Different available Millimeter (mm)

- 0.05mm (2 mil)

- Yes

- Available as per design

- Blue

- Min 0.10mm

- ENIG, OSP, HASL, Immersion Silver/Tin

- 2 Layers, 4 Layers

- UL94V-0

- Polyimide

- Customized as per project requirements

- White / Black / Custom

- 1/3oz, 1/2oz, 1oz, 2oz (customizable)

- 220-440 Volt (V)

- 100% E-Test, AOI, X-ray as required

- SMD, BGA, QFN, Fine Pitch, Through-Hole components supported

- Flexible Pcb

- Flexible PCB, Polyimide FPC

- >10^9

- Yellow, Black, Green, Blue, White

- Controlled Impedance available

- Turnkey, Consignment, Partial Turnkey

- Full SMT & Through Hole Assembly

- Yes

- 1 Piece

- Custom contours and cutouts supported

- Up to 600mm length

- ZIF, FPC, Custom Types

- Vacuum/ESD safe packaging

- Sample: 3-5 working days; Mass Production: 8-12 days

- PI, FR4, Stainless Steel

0.12mm & 0.15mm Polyimide FPC Assembly 2 & 4 Layers Flexible PCB Circuit Board Assembly Services PCBA Product Line Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

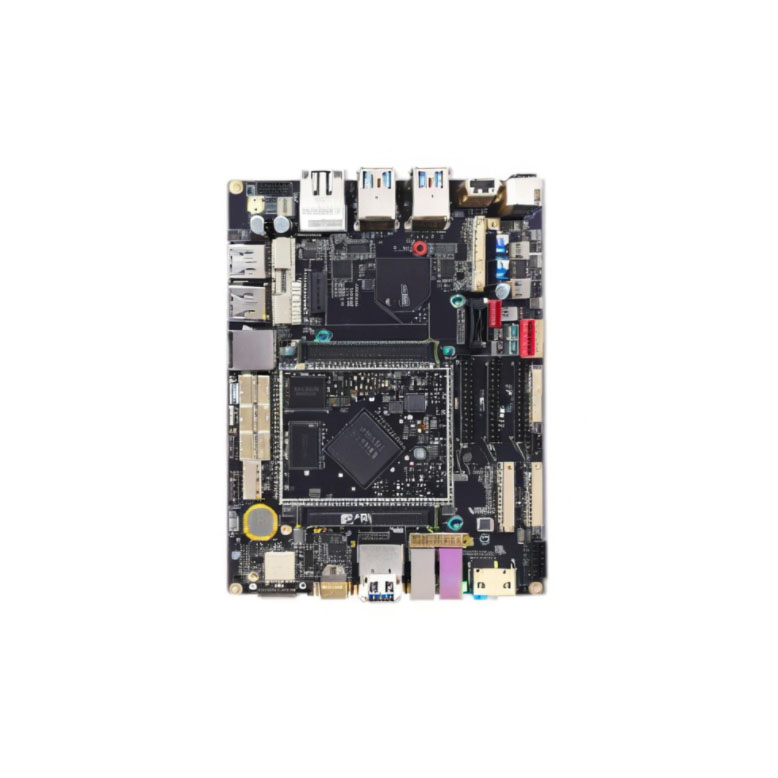

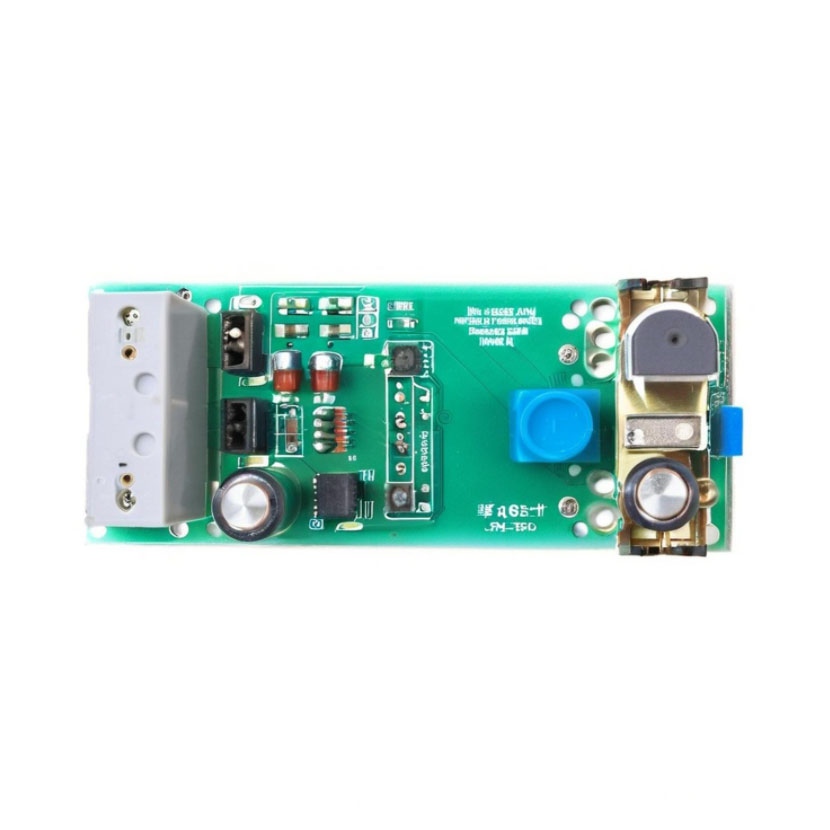

Discover enlightened efficiency with our hot-selling 0.12mm & 0.15mm Polyimide FPC Assembly, the paragon of flexible PCB technology. Designed for exceptional performance, this product line supports 2 and 4 layer configurations, accommodating full SMT and through hole assembly. Benefit from instant savings without compromising on quality, with customizable contours and cutouts, sensor switch options, and comprehensive connector types. Each board is RoHS compliant and expertly manufactured in Vietnam, with warranty and rapid turnaround. Exceptional reliability meets modern board requirements, making it a fresh solution for your next project.

Advanced Application & Features for Every Industry

Our Polyimide FPC Assembly is engineered for diverse surface applications, including smart devices, medical electronics, and automotive sectors. The flexible circuits provide precision mounting with full SMT and through hole capabilities, managed by sophisticated assembly machinery. Features include customized board shapes, controlled impedance, sensor switch integration, and proven voltage endurance up to 440V. Flame resistance and high insulation ensure safe usage, while dedicated test procedures guarantee reliable board performance.

Reliable Supply & Global Export Assurance

We offer robust supply ability for our 0.12mm & 0.15mm Polyimide FPC PCBA line, allowing seamless order processing from a minimum of 1 piece. Products are efficiently dispatched for major markets including North America, Europe, and Asia from Vietnam's leading FOB ports. Valuation matches project requirements, with rapid sample and mass production lead times. Trust our exporter, manufacturer, and supplier expertise to deliver exceptional service and value.

Advanced Application & Features for Every Industry

Our Polyimide FPC Assembly is engineered for diverse surface applications, including smart devices, medical electronics, and automotive sectors. The flexible circuits provide precision mounting with full SMT and through hole capabilities, managed by sophisticated assembly machinery. Features include customized board shapes, controlled impedance, sensor switch integration, and proven voltage endurance up to 440V. Flame resistance and high insulation ensure safe usage, while dedicated test procedures guarantee reliable board performance.

Reliable Supply & Global Export Assurance

We offer robust supply ability for our 0.12mm & 0.15mm Polyimide FPC PCBA line, allowing seamless order processing from a minimum of 1 piece. Products are efficiently dispatched for major markets including North America, Europe, and Asia from Vietnam's leading FOB ports. Valuation matches project requirements, with rapid sample and mass production lead times. Trust our exporter, manufacturer, and supplier expertise to deliver exceptional service and value.

FAQ's of 0.12mm & 0.15mm Polyimide FPC Assembly 2 & 4 Layers Flexible PCB Circuit Board Assembly Services PCBA Product Line:

Q: How does the turnkey assembly process operate for this Polyimide FPC product line?

A: Our turnkey assembly process covers everything from PCB fabrication to component sourcing, mounting, and final testing, ensuring streamlined production and quality assurance from start to finish.Q: What specific usage scenarios benefit most from these flexible PCB circuit board assemblies?

A: These assemblies are ideal for compact electronics, IoT solutions, medical devices, automotive control systems, and applications requiring complex layering and contours with robust voltage endurance.Q: When can customers expect their orders to be processed and dispatched?

A: Sample orders are processed and dispatched within 3-5 working days, while mass production orders are completed in 8-12 working days, providing rapid supply to meet time-sensitive requirements.Q: Where is the main export market for this flexible PCB assembly product line?

A: Our primary export markets include North America, Europe, and Asia, with shipments originating from leading FOB ports in Vietnam for global distribution.Q: What are the key benefits of choosing this exceptional Polyimide FPC assembly service?

A: Clients enjoy instant savings, reliability backed by warranty, flexible design options, RoHS compliance, rapid turnaround, and guaranteed electrical safety through advanced testing methods.Q: How is component mounting managed for SMD, BGA, QFN, and through-hole requirements?

A: We utilize full SMT and through-hole assembly techniques, adept at handling fine pitch, BGA, QFN, and various SMD components with precision and efficiency to meet diverse project needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Flexible PCBA' category

Back to top

Call Me Free

Call Me Free