0.12mm 0.15 mm Polyimide FPC Assembly 2 Layers 4 Layers PCB Assembly Services Circuit Board Assembly Services for Flexible PCB

Product Details:

- Board Type Flexible PCB

- Flame Resistance Level UL 94V-0

- Voltage Endurance 220-440 Volt (V)

- Impedance Controlled impedance available

- Soldermask Green / Optional

- Test 100% E-testing and AOI

- Hole Size Minimum 0.1mm

- Click to view more

X

0.12mm 0.15 mm Polyimide FPC Assembly 2 Layers 4 Layers PCB Assembly Services Circuit Board Assembly Services for Flexible PCB Price And Quantity

- 100 Piece

- Heat-resistant acrylic or epoxy

- 10% to 90% RH non-condensing

- Vacuum packing / Anti-static bags

- 0.8mm

- Available

- 5-15 days depending on order size

- Automated and manual options

- SMT & THT available

- >100,000 cycles

- Up to 250°C

- Yes

- ZIF, FFC, and custom options

0.12mm 0.15 mm Polyimide FPC Assembly 2 Layers 4 Layers PCB Assembly Services Circuit Board Assembly Services for Flexible PCB Product Specifications

- 0.05mm

- 220-440 Volt (V)

- Controlled impedance available

- Yes

- 2 Layers / 4 Layers

- 100% E-testing and AOI

- Green / Optional

- Polyimide

- Integrated as per assembly requirements

- Available on request

- ENIG / OSP / HASL

- Flexible PCB

- Green

- UL 94V-0

- Minimum 0.1mm

- 0.12mm / 0.15mm

- 0.05mm

- White

- >10^12

- Custom sizes available

- Polyimide FPC Assembly

- Different available Millimeter (mm)

- Heat-resistant acrylic or epoxy

- 10% to 90% RH non-condensing

- Vacuum packing / Anti-static bags

- 0.8mm

- Available

- 5-15 days depending on order size

- Automated and manual options

- SMT & THT available

- >100,000 cycles

- Up to 250°C

- Yes

- ZIF, FFC, and custom options

0.12mm 0.15 mm Polyimide FPC Assembly 2 Layers 4 Layers PCB Assembly Services Circuit Board Assembly Services for Flexible PCB Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

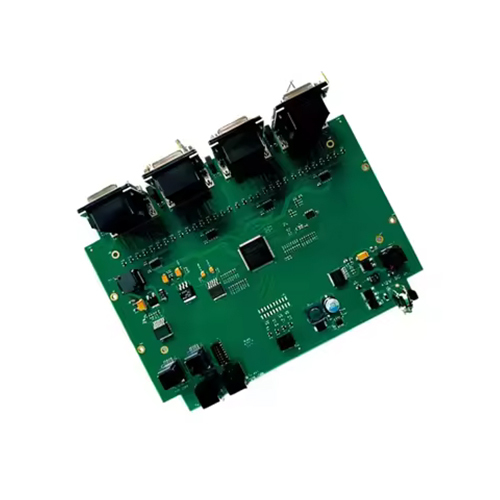

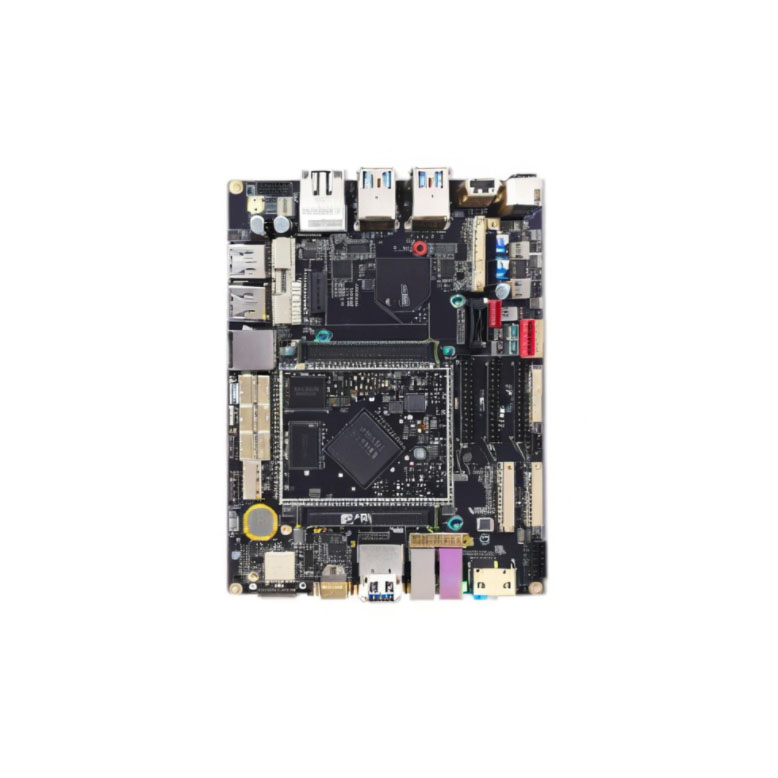

Discover our Special Polyimide FPC Assembly services, now with a stellar Price Cut for in-demand 0.12mm and 0.15mm flexible PCBs. Tailored for gilt-edged performance, our splendid assemblies offer up to 4 layers, max working temperature to 250C, and reliability over 100,000 flexibility cycles. RoHS compliant, with custom panel sizes, gold-standard SMT & THT assembly, and sensor switch integration available. Enjoy vacuum or anti-static packaging, accelerated 5-15 day lead times, and a warranty that ensures both peace of mind and enduring value. Perfect choice for exporters, manufacturers, and suppliers from Vietnam.

Exceptional Applications & Features of Polyimide FPC Assembly

Our 0.12mm / 0.15mm Polyimide FPC Assemblies shine in automotive, industrial automation, medical, and consumer electronics. These stellar machines feature automated/manual mounting, high voltage endurance, flexible design, and resistance to heat, humidity, and flame. Their splendid adaptability suits intricate circuit layouts, making them ideal for dynamic, flexible connections where reliability and space-saving are paramount.

Swift Delivery, Domestic Market Focus, and Payment Options

Transportation for our gilt-edged PCB assembly services is handled with meticulous care, ensuring an estimated delivery time of just 5-15 days, depending on your order volume. Serving the main domestic market across Vietnam, we ensure secure and prompt shipment. Flexible payment terms make ordering seamless, catering to varying requirements and contributing to efficient, cost-effective procurement.

Exceptional Applications & Features of Polyimide FPC Assembly

Our 0.12mm / 0.15mm Polyimide FPC Assemblies shine in automotive, industrial automation, medical, and consumer electronics. These stellar machines feature automated/manual mounting, high voltage endurance, flexible design, and resistance to heat, humidity, and flame. Their splendid adaptability suits intricate circuit layouts, making them ideal for dynamic, flexible connections where reliability and space-saving are paramount.

Swift Delivery, Domestic Market Focus, and Payment Options

Transportation for our gilt-edged PCB assembly services is handled with meticulous care, ensuring an estimated delivery time of just 5-15 days, depending on your order volume. Serving the main domestic market across Vietnam, we ensure secure and prompt shipment. Flexible payment terms make ordering seamless, catering to varying requirements and contributing to efficient, cost-effective procurement.

FAQ's of 0.12mm 0.15 mm Polyimide FPC Assembly 2 Layers 4 Layers PCB Assembly Services Circuit Board Assembly Services for Flexible PCB:

Q: How does the assembly process for 0.12mm/0.15mm Polyimide FPC PCB work?

A: The assembly process involves surface-mount (SMT) or through-hole (THT) technology, with automated and manual component mounting. Board testing includes 100% E-testing and automated optical inspection to ensure gilt-edged reliability.Q: What are the main benefits of choosing your flexible PCB assembly services?

A: Our services offer splendid flexibility cycles exceeding 100,000, stellar heat endurance up to 250C, and RoHS compliance. Customization, quick lead times, warranty, and robust insulation resistance set our assemblies apart.Q: When can I expect delivery after placing an order?

A: Delivery times are typically estimated between 5 to 15 days, depending on your order size and component requirements. We provide updates throughout the transportation process to keep you informed.Q: Where can these FPC assemblies be used?

A: Our Polyimide FPC assemblies are in demand for use in automotive systems, consumer electronics, industrial equipment, and medical devices where flexible, thin, and durable circuit boards are essential.Q: What connector types and packaging options do you support?

A: Connector support includes ZIF, FFC, and custom connectors; packaging options are vacuum packing or anti-static bags to ensure safe transportation and quality preservation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Flexible PCBA' category

Back to top