NOVA Robotic Company's Custom PCBA Manufacturing Assembly Multilayer Fr4 Boards with OEM PCB Layout Design Schematic Diagram

Product Details:

- Min. Line Width 0.075 mm

- Hole Size Min. 0.2 mm

- Voltage Endurance 220-440 Volt (V)

- Test 100% E-test, AOI, X-ray (available)

- Soldermask

- Silkscreen White (custom colors available)

- Flame Resistance Level UL94 V-0

- Click to view more

X

NOVA Robotic Company's Custom PCBA Manufacturing Assembly Multilayer Fr4 Boards with OEM PCB Layout Design Schematic Diagram Price And Quantity

- 100 Piece

- In-house and consignment options

- +/- 0.05 mm

- Available, including OEM PCB Layout Design Schematic Diagram

- Available

- Blind/Buried Vias, HDI (High Density Interconnect)

- Typically 7-15 working days

- Professional Engineering team for DFM and DFA review

- SMT, DIP, Mixed technology, Conformal Coating, BGA Placement

- Component Soldering, Full Turnkey Assembly Service

NOVA Robotic Company's Custom PCBA Manufacturing Assembly Multilayer Fr4 Boards with OEM PCB Layout Design Schematic Diagram Product Specifications

- 2-16 Layers (Multilayer)

- Green

- UL94 V-0

- White (custom colors available)

- High-quality FR4

- HASL, ENIG, OSP, Immersion Tin/Silver

- Different available Millimeter (mm)

- Controlled impedance available

- Yes

- Up to 600mm x 1200mm (custom sizes available)

- >10^12

- 220-440 Volt (V)

- Multilayer FR4 Board

- 0.075 mm

- PCB Board

- Min. 0.2 mm

- 0.075 mm

- Optional/Available as part of PCBA

- 1 oz (standard), custom options available

- SMT and THT Supported, BGA, QFP, SMD, IC, connectors, etc.

- 100% E-test, AOI, X-ray (available)

- In-house and consignment options

- +/- 0.05 mm

- Available, including OEM PCB Layout Design Schematic Diagram

- Available

- Blind/Buried Vias, HDI (High Density Interconnect)

- Typically 7-15 working days

- Professional Engineering team for DFM and DFA review

- SMT, DIP, Mixed technology, Conformal Coating, BGA Placement

- Component Soldering, Full Turnkey Assembly Service

NOVA Robotic Company's Custom PCBA Manufacturing Assembly Multilayer Fr4 Boards with OEM PCB Layout Design Schematic Diagram Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

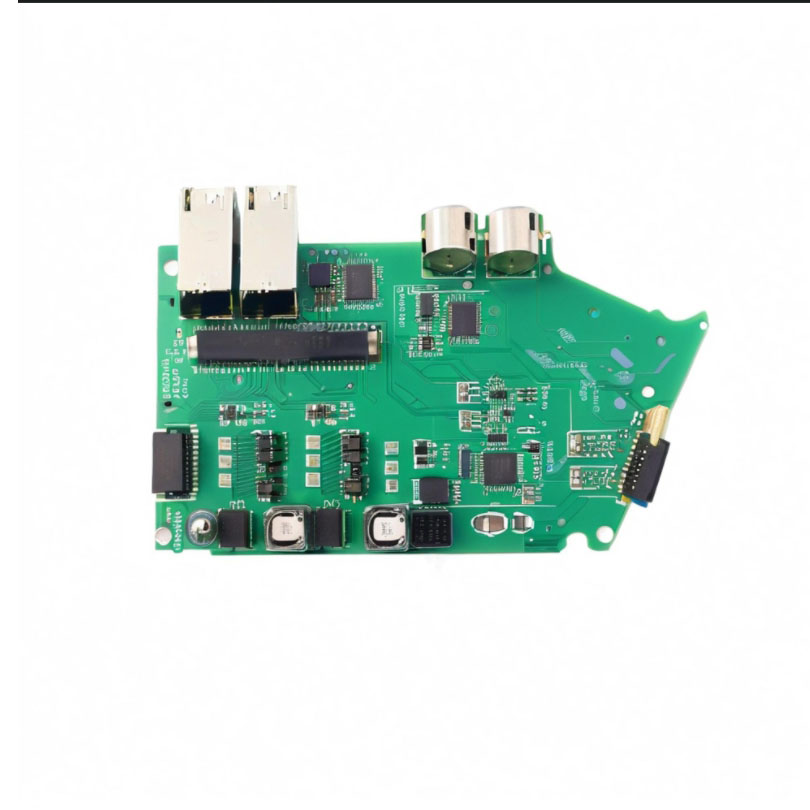

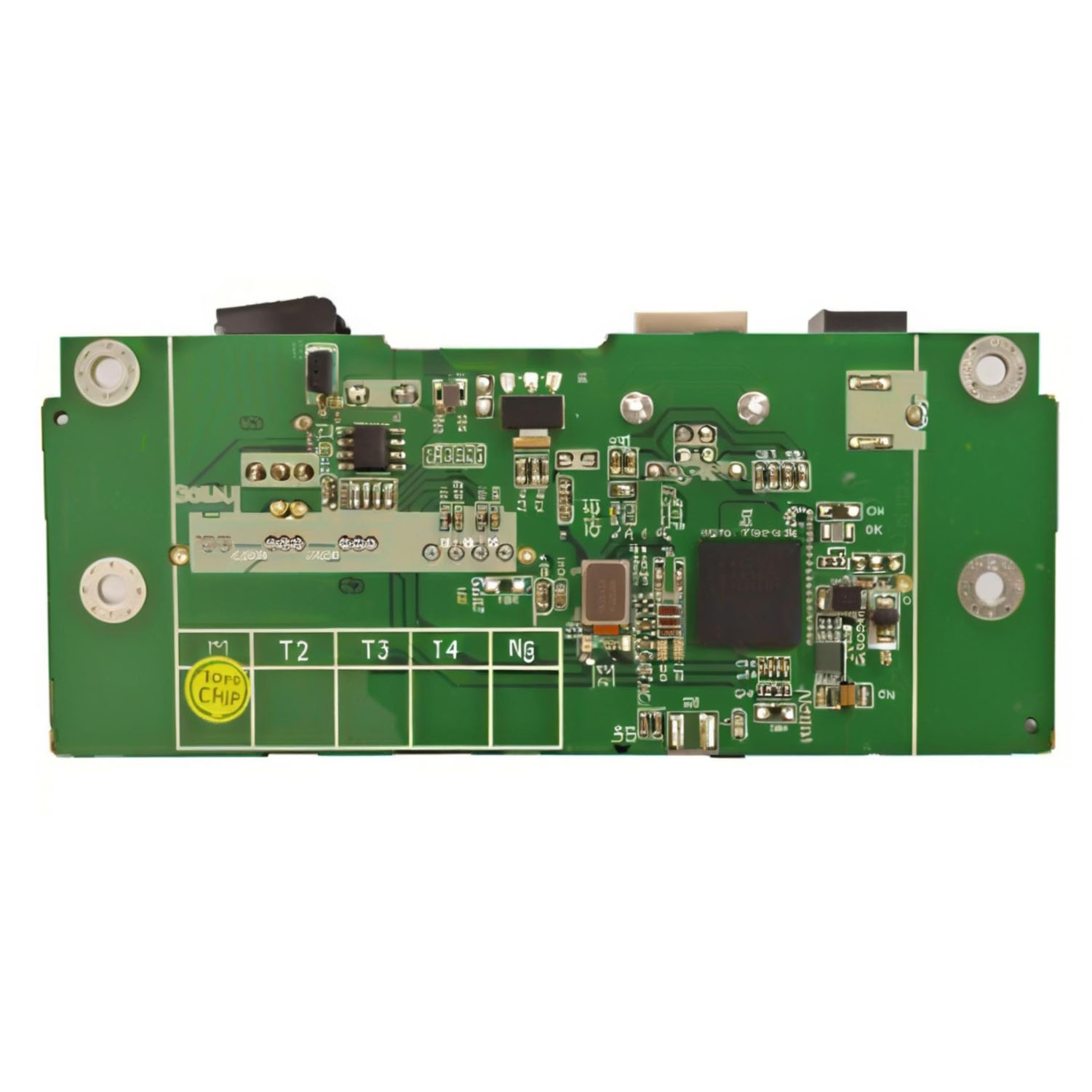

NOVA Robotic Company's Custom PCBA Manufacturing Assembly Multilayer FR4 Boards stand out as a top-tier solution, garnering favorable reviews from global clients. In demand for their grandiose OEM/ODM capabilities, these boards feature outstanding engineering support with reduced lead times, typically just 7-15 working days. With advanced SMT, DIP, mixed technology, conformal coating, and BGA placement, NOVA ensures heightened performance and exceptional quality. Custom PCB layout design, rigorous testing, full turnkey assembly, and component sourcing are available, offering unmatched flexibility for both prototype and mass production needs.

Exceptional Features and Versatile Application

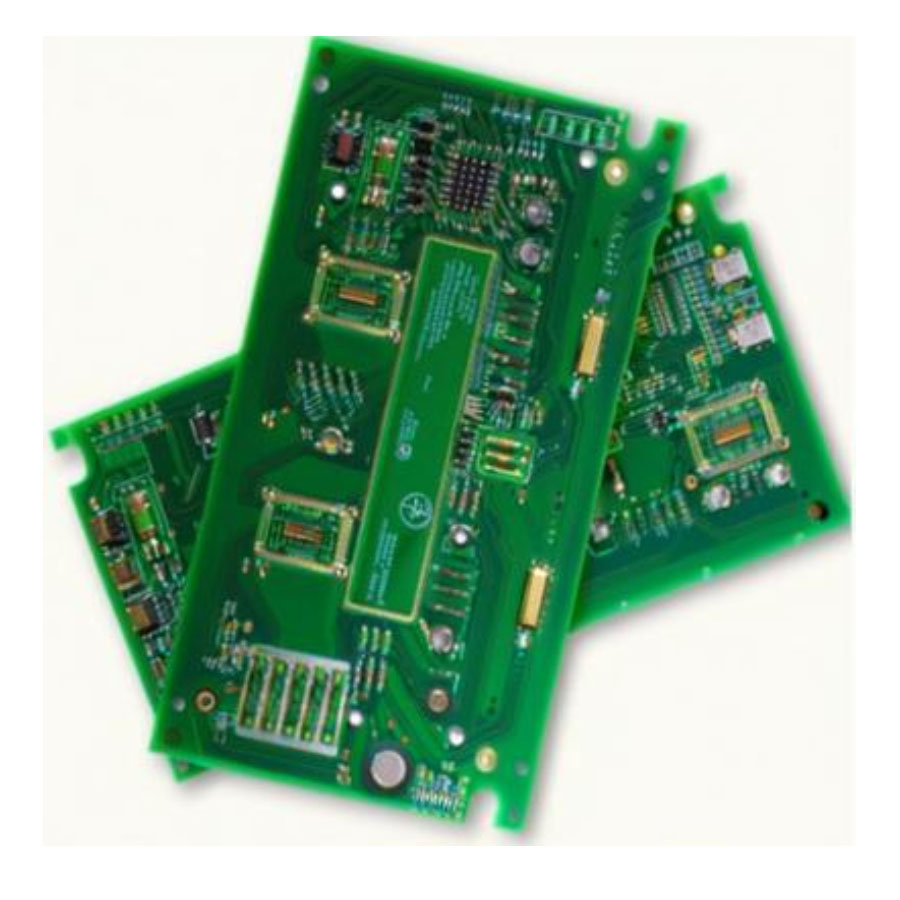

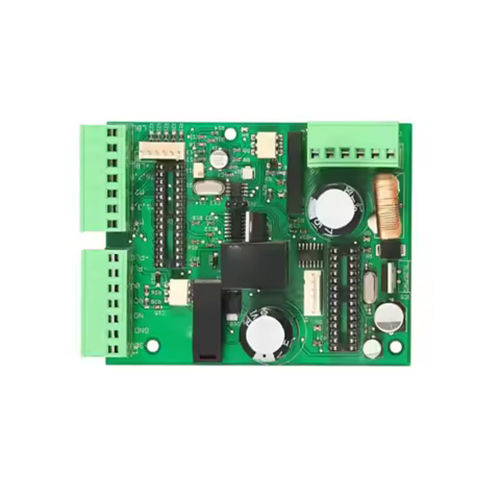

NOVA Robotic Company's Custom PCBA Multilayer FR4 Boards offer advanced features, including BGA placement, conformal coating, blind and buried vias, and controlled impedance. With options from 2 to 16 layers, these boards support both SMT and THT components. Their robust design is suitable for grandiose electronic devices, industrial controls, and sensor switches. The outstanding surface finish and green soldermask make them perfectly suited for high-quality, resilient applications across multiple industries.

Global Markets, Quick Shipping, and Reliable Packaging

NOVA Robotic Company's PCBA solutions are shipped worldwide, catering to thriving export markets such as North America, Europe, and Southeast Asia. Certified to international standards, each board is carefully packaged to ensure safety during express shipping. Stock is ready for timely delivery, and custom packaging is available based on client requirements. Clients enjoy prompt order fulfillment that meets even the most stringent manufacturing and export demands.

Exceptional Features and Versatile Application

NOVA Robotic Company's Custom PCBA Multilayer FR4 Boards offer advanced features, including BGA placement, conformal coating, blind and buried vias, and controlled impedance. With options from 2 to 16 layers, these boards support both SMT and THT components. Their robust design is suitable for grandiose electronic devices, industrial controls, and sensor switches. The outstanding surface finish and green soldermask make them perfectly suited for high-quality, resilient applications across multiple industries.

Global Markets, Quick Shipping, and Reliable Packaging

NOVA Robotic Company's PCBA solutions are shipped worldwide, catering to thriving export markets such as North America, Europe, and Southeast Asia. Certified to international standards, each board is carefully packaged to ensure safety during express shipping. Stock is ready for timely delivery, and custom packaging is available based on client requirements. Clients enjoy prompt order fulfillment that meets even the most stringent manufacturing and export demands.

FAQ's of NOVA Robotic Company's Custom PCBA Manufacturing Assembly Multilayer Fr4 Boards with OEM PCB Layout Design Schematic Diagram:

Q: How does NOVA Robotic Company ensure the quality of its custom PCBA multilayer FR4 boards?

A: Quality is maintained through a strict process that includes 100% electrical testing (E-test), Automated Optical Inspection (AOI), and X-ray analysis, ensuring every board meets top-tier industry standards.Q: What benefits do OEM/ODM services provide for clients?

A: OEM/ODM services offer complete flexibility, allowing clients to submit their unique schematic diagrams for custom PCBA production, resulting in tailored solutions for their specific project requirements.Q: When can clients expect their orders to be shipped?

A: Typical lead times are reduced to just 7-15 working days. With stock ready and express shipping available, most orders are fulfilled quickly and efficiently.Q: Where can the custom PCBA boards be used?

A: These outstanding boards support usage across various sectors such as industrial automation, consumer electronics, high-density applications, and sensor integration.Q: What surface finishes are available for the multilayer FR4 boards?

A: NOVA Robotic offers a selection of surface finishes, including HASL, ENIG, OSP, Immersion Tin, and Silver, with custom finish options available to suit distinct product needs.Q: How does the assembly process accommodate different component sourcing options?

A: Component sourcing is highly flexible, with both in-house and consignment options available to streamline assembly, whether for small batches or full turnkey projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Multilayer PCBA' category

Back to top