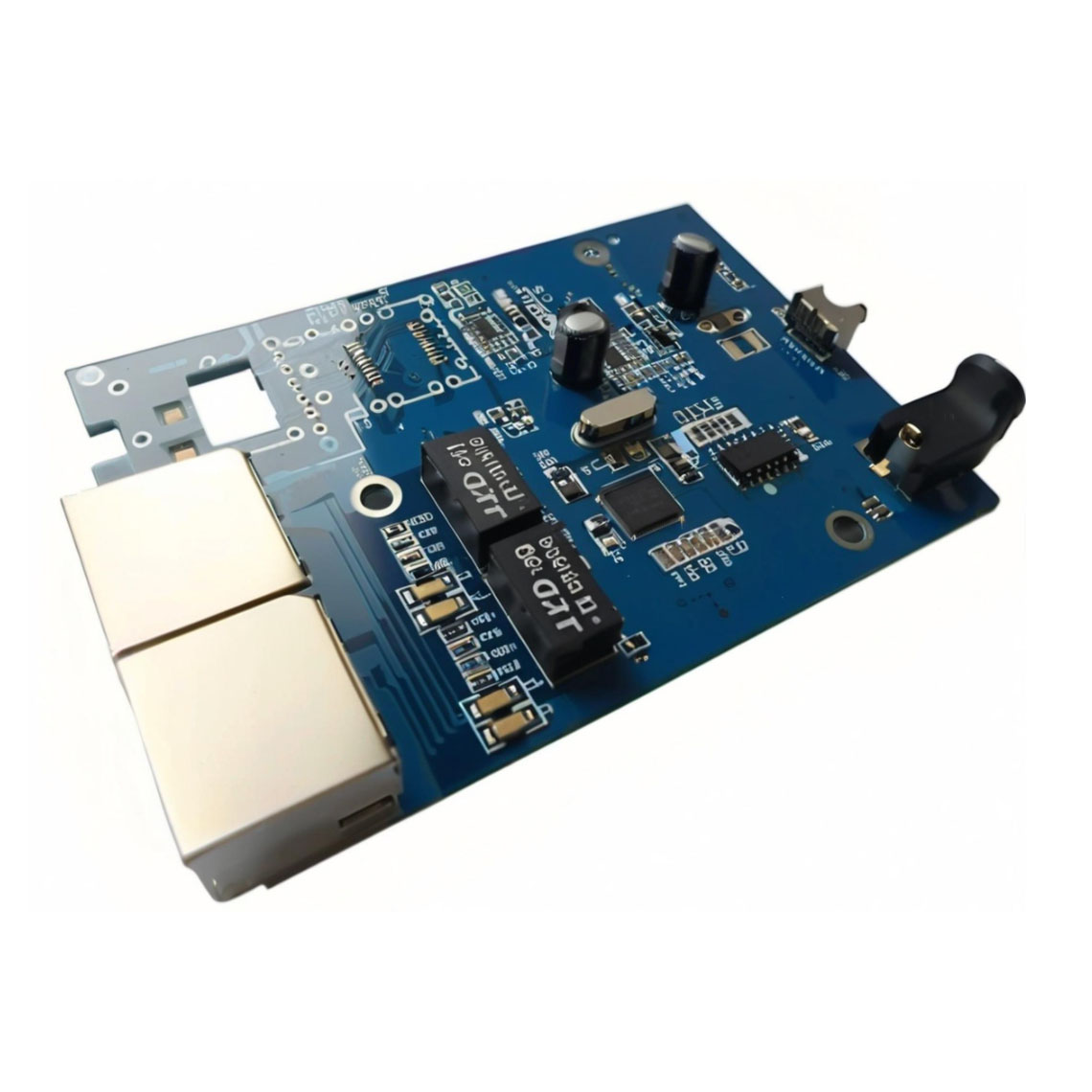

NOVA Medical Integrated Electronic Pcb Sterilizer Device Circuit Board OEM FR4 Multilayer from a Reliable PCBA Plant

Product Details:

- Soldermask Green, various colours available

- Silkscreen Green

- Board Type Multilayer

- Min. Line Spacing 0.076mm

- Insulation Resistance >10^12

- Test 100% E-test functional

- Voltage Endurance 220-440 Volt (V)

- Click to view more

X

NOVA Medical Integrated Electronic Pcb Sterilizer Device Circuit Board OEM FR4 Multilayer from a Reliable PCBA Plant Price And Quantity

- 100 Piece

- 5-15 Days

- Through hole and SMD

- ESD Anti-static Package

- SMT and THT

- -20°C to +85°C

- 1 PCS

- Available

- Integrated sterilization control

- Medical Sterilizer Devices

NOVA Medical Integrated Electronic Pcb Sterilizer Device Circuit Board OEM FR4 Multilayer from a Reliable PCBA Plant Product Specifications

- Green

- 220-440 Volt (V)

- 100% E-test functional

- Fully populated

- >10^12

- 0.076mm

- Integrated

- Different available Millimeter (mm)

- UL94-V0

- Yes

- 1oz to 3oz

- PCB Board

- 2-12 layers

- Min 0.2mm

- FR4

- Controlled impedance supported

- HASL, ENIG, OSP

- Multilayer

- Customized

- 0.076mm

- Green, various colours available

- Green

- 5-15 Days

- Through hole and SMD

- ESD Anti-static Package

- SMT and THT

- -20°C to +85°C

- 1 PCS

- Available

- Integrated sterilization control

- Medical Sterilizer Devices

NOVA Medical Integrated Electronic Pcb Sterilizer Device Circuit Board OEM FR4 Multilayer from a Reliable PCBA Plant Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

Discover prodigious reliability and unrivaled flexibility with the NOVA Medical Integrated Electronic PCB Sterilizer Device Circuit Board OEM FR4 Multilayer, expertly engineered in a first-class, rarefied PCBA plant from Vietnam. Affordable yet advanced, this device offers seamless personalisation, supporting both SMT and THT processes. Its integrated sterilization control functions are ideal for medical sterilizer applications. Explore custom panel sizes, robust flame resistance (UL94-V0), and broad operating temperature range (-20C to +85C) for dependable performance. Benefit from ESD anti-static packing, quick lead times, and dedicated OEM/ODM service, all under warranty.

Optimal Application Sites and Surfaces

The NOVA Medical Integrated Electronic PCB Sterilizer is specifically designed for medical sterilizer devices, providing exceptional sterilization control directly within medical equipment. Its versatile mounting options-through hole and SMD-enable integration on varied surfaces and device platforms. The multilayer construction accommodates complex medical environments, ensuring consistent performance across diverse application surfaces, from tabletop units to large-scale sterilization chambers.

FOB Port, Samples, and Supply Capability

Quotation requests are welcome for shipments via Vietnam's major FOB ports, ensuring express shipping and quick dispatch worldwide. The supply ability extends to large-scale orders, supported by a sample policy that streamlines project prototyping before bulk commitments. Fast lead times (5-15 days) enable efficient production cycles, allowing partners to explore and assess product quality with confidence before scaling up operations.

Optimal Application Sites and Surfaces

The NOVA Medical Integrated Electronic PCB Sterilizer is specifically designed for medical sterilizer devices, providing exceptional sterilization control directly within medical equipment. Its versatile mounting options-through hole and SMD-enable integration on varied surfaces and device platforms. The multilayer construction accommodates complex medical environments, ensuring consistent performance across diverse application surfaces, from tabletop units to large-scale sterilization chambers.

FOB Port, Samples, and Supply Capability

Quotation requests are welcome for shipments via Vietnam's major FOB ports, ensuring express shipping and quick dispatch worldwide. The supply ability extends to large-scale orders, supported by a sample policy that streamlines project prototyping before bulk commitments. Fast lead times (5-15 days) enable efficient production cycles, allowing partners to explore and assess product quality with confidence before scaling up operations.

FAQ's of NOVA Medical Integrated Electronic Pcb Sterilizer Device Circuit Board OEM FR4 Multilayer from a Reliable PCBA Plant:

Q: How does the NOVA Medical PCB Sterilizer ensure reliable sterilization control in medical devices?

A: The device integrates sophisticated sterilization control circuitry, fully populated with electrical components, and supports both through hole and SMD mounting. This design guarantees consistent functionality and optimal performance within various medical sterilizer devices.Q: What is the process for OEM/ODM personalisation of the PCB sterilizer device?

A: Customers can personalise circuit design, panel size, and specifications through the OEM/ODM service. The plant's expertise allows tailoring features such as silkscreen colour, copper thickness, and multilayer configurations to meet specific project requirements.Q: When can buyers expect delivery after placing an order for the PCB sterilizer device?

A: With a lead time of 5-15 days, the PCB sterilizer device is quickly dispatched following order confirmation, ensuring timely delivery for prototypes and bulk shipments via express shipping channels.Q: Where is the NOVA Medical Integrated Electronic PCB Sterilizer Device manufactured and shipped from?

A: The device is manufactured by a reliable PCBA supplier in Vietnam and shipped globally via major FOB ports, offering flexible international logistics for exporters, suppliers, and manufacturers.Q: What are the main benefits of using this multilayer PCB in medical sterilizer devices?

A: Benefits include high voltage endurance (220-440 V), robust flame resistance, controlled impedance, extensive insulation resistance, and guaranteed functionality through 100% E-test assurance. The product enhances operational safety and efficiency in demanding medical environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Multilayer PCBA' category

Back to top

Call Me Free

Call Me Free