SMT PCB Assembly with OEM Service Manufacturer Sewing Machine Circuit Board

1.0 आईएनआर

उत्पाद विवरण:

X

मूल्य और मात्रा

- 1

- SMT (Surface Mount Technology) PCB Assembly

- 1-32 Layers (customizable)

- SMT, THT, Coating, Post Soldering, Testing

- Customizable as per client requirement

- Sewing Machine

- Minimum 0.2mm

- As fast as 24-48 hours

- 100% Functional Test, AOI, X-ray Inspection

- ±0.03mm (SMT)

- Supported

- High TG FR4

- Up to 600mm x 1200mm

- From 0.6mm up to 3.2mm

- HASL, ENIG, OSP, Immersion Silver, Immersion Tin

- Optional

- -40°C ~ +85°C

- Gerber, BOM, CAD, PCB file

- 50000 टुकड़ा/टुकड़ाs per Month

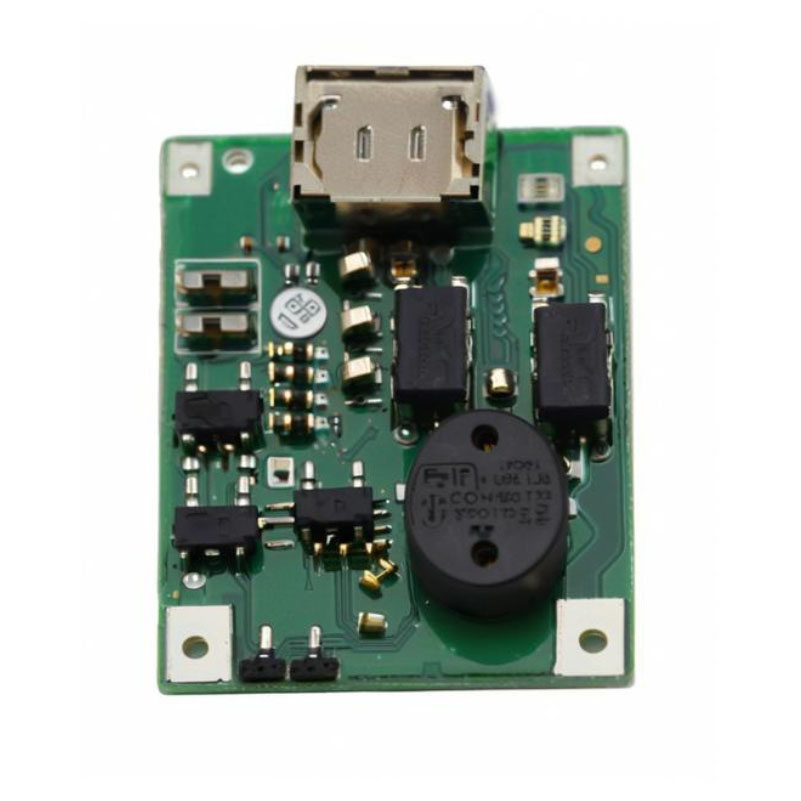

- SMT PCB Assembly with OEM Service Manufacturer Sewing Machine Circuit Board

- Standard Export Carton

- 1oz - 3oz (customizable)

- Green (customizable options: Blue, Red, Black, White, Yellow)

- White/Black/Yellow (Customizable)

- 1 टुकड़ा

- China

- Single-Sided & Double-Sided SMT PCB

- Support Passive/Active, Brand Components

- Available

उत्पाद विवरण

Experience the best-seller SMT PCB Assembly with OEM Service, specifically engineered for sewing machine circuit boards. Enjoy dazzling performance with top-tier customization options, including magnificent single-sided or double-sided assembly and fresh access to advanced impedance control. Crafted from high TG FR4 material, with dimensions and layers tailored to your requirements, this product delivers unmatched reliability in demanding environments. Benefit from rapid prototyping, secure mounting accuracy of 0.03mm, versatile solder mask and silkscreen colors, and a swift lead time. Trusted by global manufacturers seeking best-in-class quality and export excellence.

Versatile Application & Advanced Features

The SMT PCB Assembly is designed exclusively for sewing machine circuit boards, offering users robust performance and precision. Advantage lies in its customizable layers, board dimensions, and advanced impedance control-making it ideal for specialized electronics. Extra features such as optional conformal coating, choice of silkscreen and solder mask colors, and stringent functional testing assure dazzling reliability in various industrial settings, tailored to your project specifications.

Payment, Packaging & Sample Availability

Benefit from secure payment terms and stock ready for swift order fulfillment. Each board is carefully packed in a standard export carton to ensure secure shipping to your export market destination. Samples are available for clients seeking hands-on evaluation before bulk orders. With flexible MOQ starting at just one piece and supply capacity of up to 50,000 pieces per month, you enjoy accessibility and efficiency for every procurement need.

Versatile Application & Advanced Features

The SMT PCB Assembly is designed exclusively for sewing machine circuit boards, offering users robust performance and precision. Advantage lies in its customizable layers, board dimensions, and advanced impedance control-making it ideal for specialized electronics. Extra features such as optional conformal coating, choice of silkscreen and solder mask colors, and stringent functional testing assure dazzling reliability in various industrial settings, tailored to your project specifications.

Payment, Packaging & Sample Availability

Benefit from secure payment terms and stock ready for swift order fulfillment. Each board is carefully packed in a standard export carton to ensure secure shipping to your export market destination. Samples are available for clients seeking hands-on evaluation before bulk orders. With flexible MOQ starting at just one piece and supply capacity of up to 50,000 pieces per month, you enjoy accessibility and efficiency for every procurement need.

FAQ's of SMT PCB Assembly with OEM Service Manufacturer Sewing Machine Circuit Board:

Q: How do I specify custom dimensions and layer requirements for my SMT PCB order?

A: You can provide your custom dimensions and layer specifications via accepted data formats such as Gerber, BOM, CAD, or PCB files at the time of placing your order. Our OEM service ensures your specific requirements are met precisely.Q: What is the advantage of choosing single-sided or double-sided SMT PCB assembly?

A: Selecting single-sided or double-sided SMT PCB allows greater flexibility in circuit design, catering to both simple and complex sewing machine applications. Double-sided assemblies support higher component density and more sophisticated functions.Q: When can I expect my prototype order to be ready?

A: Prototype orders can be processed with lead times as fast as 24-48 hours, ensuring rapid development and reduced time-to-market for your sewing machine electronics projects.Q: Where is the SMT PCB Assembly manufactured and shipped from?

A: All SMT PCB Assemblies are manufactured in China. Secure shipping is provided using standard export cartons for global distribution to your export market.Q: What testing and quality assurance processes are performed on each circuit board?

A: Each board undergoes comprehensive testing, including 100% functional tests, AOI (Automated Optical Inspection), X-ray inspection, and reliability checks to guarantee superior performance and dazzling accuracy.Q: How does the OEM service benefit sewing machine manufacturers?

A: OEM service offers manufacturers the flexibility to customize circuit boards to fit unique sewing machine designs, provides access to premium brand components, and ensures tailored support throughout the ordering process.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

पीसीबीए सेवाएँ अन्य उत्पाद

Back to top

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें