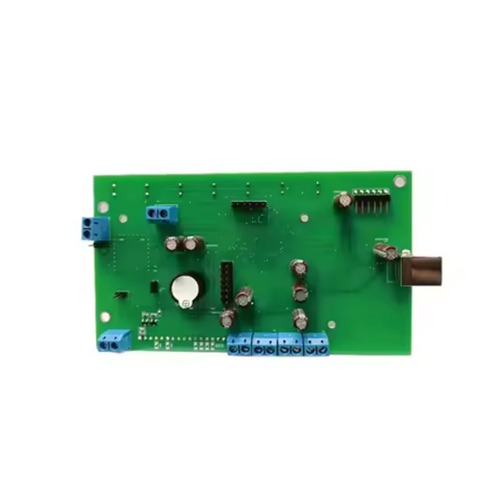

Custom FPC Flexible Printed Circuit Board Assembly Electronic PCBA

Product Details:

- Min. Line Spacing 0.075mm (3mil)

- Insulation Resistance >10^12

- Silkscreen White or Yellow

- Board Type Flexible PCB (FPC)

- Test 100% AOI, E-test, Function Test

- Voltage Endurance 220-440 Volt (V)

- Min. Line Width 0.075mm (3mil)

- Click to view more

X

Custom FPC Flexible Printed Circuit Board Assembly Electronic PCBA Price And Quantity

- 100 Piece

- Consumer electronics, automotive, medical devices

- ZIF / FFC / Custom

- High bend radius, up to 360° foldable

- 10-15 working days

- Yes

- Standard anti-static bag

- -20°C to +85°C

Custom FPC Flexible Printed Circuit Board Assembly Electronic PCBA Product Specifications

- 0.075mm (3mil)

- 220-440 Volt (V)

- 0.075mm (3mil)

- Optional integration

- Customizable

- >10^12

- 1-8 Layers

- 94V-0

- 1oz / 2oz / Custom

- Yes

- White or Yellow

- Printed Circuit Board Assembly Electronic PCBA

- Polyimide / PET

- Flexible PCB (FPC)

- Min 0.2mm

- ENIG / OSP / HASL / Custom

- Green / Black / Yellow / Custom

- Green

- Custom as per BOM

- Custom controlled

- 100% AOI, E-test, Function Test

- Different available Millimeter (mm)

- Consumer electronics, automotive, medical devices

- ZIF / FFC / Custom

- High bend radius, up to 360° foldable

- 10-15 working days

- Yes

- Standard anti-static bag

- -20°C to +85°C

Custom FPC Flexible Printed Circuit Board Assembly Electronic PCBA Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

Redeem the rarefied advantages of our Custom FPC Flexible Printed Circuit Board Assembly (Electronic PCBA), renowned for its high bend radius and astonishing 360 foldability. Designed for a cost-effective solution leveraging enviable flexibility, it operates efficiently from -20C to +85C with ZIF/FFC/custom connectors. This RoHS-compliant marvel, delivered in a standard anti-static bag, serves consumer electronics, automotive, and medical industries. With customizable panel sizes, layers (1-8), copper and board thickness, and optional sensor switch integration, our product ensures lasting value. Redeem special rates for bulk orders, delivered within 10-15 working days.

Diverse Applications & Seamless Operation

Our Custom FPC Flexible Printed Circuit Board Assembly is adept not just in standard electronics, but also excels in automotive dashboards, wearable medical devices, and home automation systems. Its user-friendly design ensures easy installation; simply align the connectors and secure as per your specification. With robust features like high durability, flame resistance, customizable layers, and optional sensor switches, it's engineered to meet a wide range of flexible electronic requirements with reliability and precision.

Global Export, Efficient Logistics & Supply Chain Excellence

We proudly handover Custom FPC Flexible PCBA solutions to key markets including the USA, Europe, Japan, Korea, and Southeast Asia. Flexible transport services ensure timely shipment from our Vietnam FOB port. By maintaining enviable supply rates, we meet large-scale demands efficiently while guaranteeing consistent quality. Our extensive experience as exporter, manufacturer, and supplier positions us to offer smooth international transactions and prompt delivery, supporting your business's needs globally.

Diverse Applications & Seamless Operation

Our Custom FPC Flexible Printed Circuit Board Assembly is adept not just in standard electronics, but also excels in automotive dashboards, wearable medical devices, and home automation systems. Its user-friendly design ensures easy installation; simply align the connectors and secure as per your specification. With robust features like high durability, flame resistance, customizable layers, and optional sensor switches, it's engineered to meet a wide range of flexible electronic requirements with reliability and precision.

Global Export, Efficient Logistics & Supply Chain Excellence

We proudly handover Custom FPC Flexible PCBA solutions to key markets including the USA, Europe, Japan, Korea, and Southeast Asia. Flexible transport services ensure timely shipment from our Vietnam FOB port. By maintaining enviable supply rates, we meet large-scale demands efficiently while guaranteeing consistent quality. Our extensive experience as exporter, manufacturer, and supplier positions us to offer smooth international transactions and prompt delivery, supporting your business's needs globally.

FAQ's of Custom FPC Flexible Printed Circuit Board Assembly Electronic PCBA:

Q: How does the Custom FPC Flexible Printed Circuit Board Assembly accommodate high bend radius applications?

A: Our FPC PCBA is engineered with a rarefied high bend radius, allowing up to 360 foldability, making it ideal for devices that demand flexibility, such as wearable electronics, foldable gadgets, and intricate medical equipment.Q: What are the main benefits of choosing your PCBA for automotive and medical devices?

A: The product offers astonishing durability, flame resistance (94V-0), and can operate within a temperature range of -20C to +85C. Its enviable flexibility and customizable size make it particularly suited for the demanding environments of automotive dashboards and medical instruments.Q: When can I expect delivery after placing an order?

A: We ensure rapid handover of your order. Typically, the lead time is 10-15 working days after confirming specifications and payments, with prompt shipment through reliable transport services from our Vietnam FOB port.Q: Where is your primary export market and which transport services do you use?

A: Our primary export markets include the USA, Europe, Korea, Japan, and Southeast Asia. We utilize highly reputable international transport partners to guarantee secure and punctual delivery of every shipment.Q: What processes are involved in testing and quality assurance for these FPC PCBAs?

A: Each assembly undergoes 100% AOI, E-test, and full function tests to ensure rarefied quality control. With RoHS compliance and custom electrical component integration, our quality processes match industry-leading standards.Q: How can clients benefit from your cost-effective PCBA solutions?

A: Clients receive technologically advanced, custom-engineered assemblies at special rates, optimizing project budgets without compromising on reliability, performance, or compliance with international standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Flexible PCBA' category

Back to top